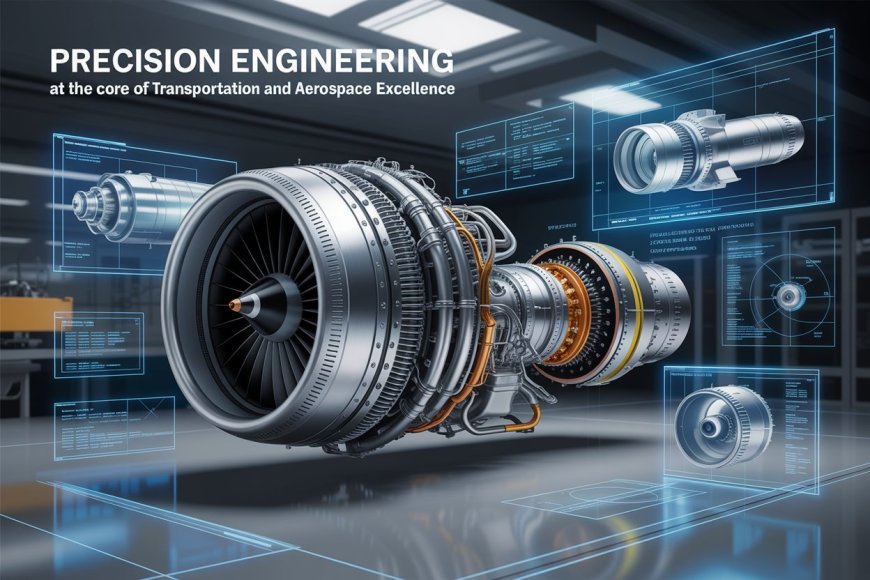

Precision Engineering at the Core of Transportation and Aerospace Excellence

Explore how differential housing for trains, aerospace precision machining, and engine component manufacturing are shaping safe, efficient, and sustainable transportation systems worldwide.

Precision engineering is critical to the current appearance of transportation and aerospace. Differential housing of trains, precision machining of the aerospace and manufacturing of the engine parts require high predetermined quality and performance levels of each component. These elements aid safety, efficiency and innovation. As the demand for reliability increases under challenging circumstances, manufacturers are increasingly engaged in developing their technologies. Rail to airline engines' precision is the driving force in progress. So, how are these files crucial components designed and manufactured?

Differential Housing for Trains: Strength and Reliability

They have compartments that are called the Differential Housing For Trains, which protect the gear assembly. It also makes sure that huge forces that are created during operation are spread uniformly throughout the drivetrain. This housing should be resistant to heavy wear and stress under long journeys, since trains are very large and heavy. These housings are usually cast and machined in high-grade steel or an alloy of high-grade steel. Their perfection during construction is directly related to train performance and safety. Producers make strict checks to ensure durability and straightness.

The Manufacturing Process of Train Differential Housing

Designing various housing for trains starts by choosing the right material to accommodate high pressures. Computer-aided design (CAD) and finite element analysis (FEA) are generally used by engineers to optimize the shape of the housing in terms of strength. The casting is made in the most basic form and the final dimensions are then obtained using precision machining. Machinists measure in microns to ensure a perfect fit of gears and axles. The housing is heat-treated to increase strength after machining. Housings are checked upon delivery to halls against cracks, balance, and dimensional inaccuracy.

Precision Machining for Aerospace: Meeting High-Stakes Demands

Accuracy is paramount when precision machining for aerospace is involved. Aerospace components tend to work under high-speed, high-temperature, and high-pressure conditions. Parts such as turbine blades, fuselage fittings, and landing gear components must have tolerances so precise that any minute discrepancy would jeopardize performance. Producers employ multi-axis CNC equipment and sophisticated software to meet these requirements. Materials such as titanium and aluminum, aerospace-grade, are prevalent because of the strength-to-weight ratio. The whole process is such that parts are strong, lightweight, fatigue-resistant, and corrosion-resistant.

Technology Behind Aerospace Machining Precision

The key to aerospace precision machining is marrying cutting-edge equipment with specialized craftsmanship. Computer-controlled machinery in modern machining centers controls tool paths down to microns. Methods like electrical discharge machining (EDM) and laser cutting offer further precision for intricate shapes. Companies also spend a lot of money on real-time inspection systems to detect even minor mistakes during production. From prototype to actual delivery, aerospace machining is strictly regulated. All these measures ensure flight safety and fuel efficiency.

Engine Component Manufacturing: Powering Performance

Engine component production is the backbone of transportation, whether by train, plane, or automobile. Every component, from crankshafts and valves to pistons, has to be able to endure blazing heat, friction, and pressure. Accuracy in manufacturing allows them to fit and operate without a hitch, making the most of fuel consumption while keeping emissions to a minimum. High-strength alloys and thermal coatings also extend their lifespan. CNC machining, forging, and casting are some of the widely used methods. These processes are aimed at developing strength without unnecessary weight addition, essential in both the automotive and aerospace industries.

Quality Control in Engine Component Production

High standards of component manufacturing are assured by incorporating quality control at every step. State-of-the-art metrology instruments such as coordinate measuring machines (CMMs) ensure component measurement. Surface treatments and coatings are checked for uniformity and adhesion. Non-destructive examination techniques, such as X-ray and ultrasonic testing, detect internal defects. Manufacturers usually conduct simulation tests to foretell the performance of parts in real-life scenarios. This precision avoids expensive breakdowns and guarantees adherence to international standards. Accuracy in engine manufacturing is directly related to operational reliability.

Sustainability in Precision Manufacturing

Sustainability has become a key focus across manufacturing sectors, including transportation and aerospace. Companies are adopting eco-friendly materials, energy-efficient machines, and processes that minimize waste. For example, recycling metal shavings from machining operations and using water-based coolants reduces environmental impact. In aerospace, lightweight designs help lower fuel consumption and emissions. Similarly, in rail transport, durable components extend service life and reduce the need for frequent replacements. The integration of green practices not only supports the planet but also enhances long-term cost efficiency for industries striving for innovation and responsibility.

Conclusion

From differential housing for trains through precision machining for aerospace to engine component manufacturing, precision engineering is defining the future of mobility. With industries calling for greater efficiency and sustainability, producers are moving forward with new materials and intelligent processes. The emphasis continues to be on gaining unparalleled accuracy, strength, and endurance. Innovators such as SYNRONTECH are leading the way, providing cutting-edge solutions for these essential components.