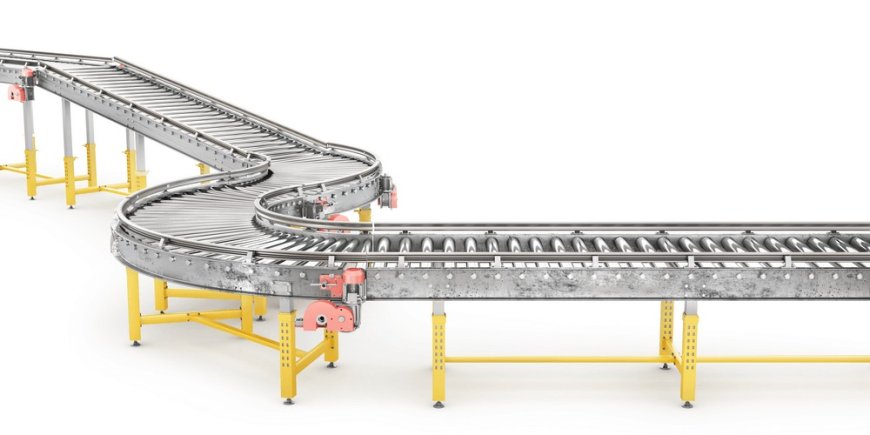

Conveyor Chains Explained: How The Right Parts Keep Heavy-Duty Systems Moving

Some materials are too heavy, hot, or bulky for standard conveyors, which is why conveyor chains are sometimes necessary. These systems are built to carry loads that would break or jam belt-driven conveyors. To keep them running smoothly, every part down to the last sprocket or tensioner has to match the job.

Chain-driven systems play a big role in everything from automotive factories to pallet-moving operations. They rely on the right conveyor parts to handle pressure, wear, and constant use without failing.

What Is a Conveyor Chain?

A conveyor chain is a series of links connected by pins, usually made from steel or hardened alloys. These chains run over sprockets and pull the load along a set path. Theyre often used in systems where products are:

- Too heavy for belt conveyors

- Carried on fixtures or pallets

- Moved through high-temperature or abrasive environments

Unlike a belt, a chain doesnt stretch much, doesnt slip, and can handle rougher treatment. Thats why chain-driven systems are standard in automotive manufacturing, heavy equipment plants, and some warehouse automation setups.

Conveyor Parts

Every chain system includes various parts that make them work. They rely on a combination of conveyor parts that all work together. If one part fails, the entire system can go down.

Some of the essential components include:

- Drive and tail sprockets: These grip the chain and drive it forward or redirect its movement

- Wear strips and track guides: These keep the chain aligned and reduce friction

- Bearings and shafts: Support the sprockets and carry load weight

- Tensioners: Maintain proper chain tension to prevent slack or binding

- Chain attachments: Brackets or mounts used to hold pallets, fixtures, or parts being moved

Each of these parts must be compatible with the type of chain and the specific demands of your system, including load weight, speed, temperature, and exposure to debris or liquids.

Matching Chain Type to the Application

Here are a few common types and where theyre used:

- Roller chain: For general applications; often used in moderate-load conveyor systems

- Drag chain: For moving bulk materials like sand or grain

- Slat chain: For carrying objects on flat platforms, often in assembly or packaging lines

- Tabletop chain: Often found in bottling and food production lines where precise, clean movement is needed

Choosing the wrong chain type can cause wear, product damage, or total breakdowns. Thats why matching the chain and the rest of the parts to the work the conveyor system will handle is important.

Real-World Example: Automotive Frame Assembly

Consider an auto plant that moves vehicle frames from one station to the next using a heavy-duty conveyor chain. Each frame sits on a large pallet with locating pins, and the chain pulls the pallet through welding, inspection, and final assembly.

This system uses:

- Dual-strand roller chain with hardened pins

- Custom brackets attached to the chain to support the frame pallets

- Precision sprockets and shafting to drive the chain smoothly

- Lubrication systems and chain guides to reduce wear and heat

If any of these parts fail, production stops. Thats why these systems are built for durability and maintained on a strict schedule.

What Happens When the Wrong Parts Are Used?

Lets say you install a chain system rated for light loads but then try to move heavy items like metal castings. The chain might stretch, bearings could wear out early or the drive sprockets might slip or break teeth.

Failures like this cost money and time. Swapping out conveyor parts after installation is far more expensive than selecting the right ones at the start.

Maintenance and Upkeep

Even the strongest chain systems need upkeep. Heres what to keep an eye on:

- Chain stretch: Over time, links wear and spacing increases. This affects timing and alignment.

- Sprocket wear: Teeth lose shape and can cause the chain to jump or slip.

- Lubrication: Keeping the chain clean and oiled reduces friction and extends its life.

- Fasteners and brackets: Loose or missing hardware can damage the chain or cause jams.

Many companies keep replacement parts on-site to fix issues without shutting down production for long.

Final Thoughts

A conveyor chain system handles jobs that belt conveyors cant. Its tough, consistent, and built for hard work, but it will only run as well as the parts that support it.

Choosing high-quality, application-specific parts makes the system safer, faster, and more reliable.