Industry 4.0 Market Report 2025 | Growth, Trends & Forecast by 2033

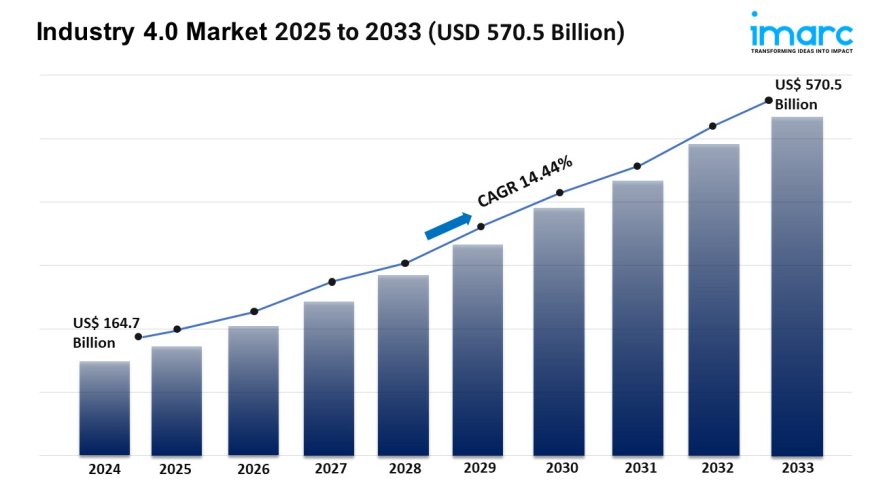

The global industry 4.0 market size reached USD 164.7 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 570.5 Billion by 2033, exhibiting a growth rate (CAGR) of 14.44% during 2025-2033.

Market Overview:

The industry 4.0 market is experiencing rapid growth, driven by adoption of advanced automation technologies, increased connectivity through IoT, and emphasis on sustainability and green manufacturing. According to IMARC Group's latest research publication, "Industry 4.0 Market Size, Share, Trends and Forecast by Component, Technology Type, End Use Industry, and Region, 2025-2033." the global industry 4.0 market size reached USD 164.7 Billionin 2024. Looking forward, IMARC Group expects the market to reachUSD 570.5 Billionby 2033, exhibiting a growth rate(CAGR) of 14.44%during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Download a sample PDF of this report: https://www.imarcgroup.com/industry-4-0-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends and Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Growth Factors in the Industry 4.0 Market

- Adoption of Advanced Automation Technologies

The widespread adoption of advanced automation technologies is a significant driver of growth in the Industry 4.0 market. Factories are increasingly integrating robotics, artificial intelligence (AI), and machine learning to streamline operations and enhance productivity. For instance, automotive manufacturers like Tesla utilize robotic assembly lines to produce electric vehicles with precision and efficiency, reducing human error and accelerating production timelines. These technologies enable real-time data analysis, predictive maintenance, and optimized workflows, allowing businesses to cut costs and improve output quality. As companies across sectors like manufacturing, logistics, and healthcare embrace automation, the demand for smart systems continues to surge, fueling market expansion.

- Increased Connectivity Through IoT

The Internet of Things (IoT) is revolutionizing industrial processes by enabling seamless connectivity between devices, machines, and systems. IoT facilitates real-time monitoring and data exchange, creating interconnected ecosystems that enhance operational efficiency. A notable example is General Electrics use of IoT in its Predix platform, which monitors industrial equipment to predict maintenance needs, reducing downtime and costs. This connectivity allows businesses to make data-driven decisions, optimize supply chains, and improve resource management. As IoT adoption grows, industries are leveraging interconnected devices to create smarter, more responsive production environments, driving significant growth in the Industry 4.0 market.

- Emphasis on Sustainability and Green Manufacturing

Sustainability is a key growth factor as industries align with global environmental goals. Industry 4.0 technologies, such as energy-efficient systems and data analytics, enable companies to reduce waste and energy consumption. For example, Siemens has implemented digital twinsvirtual replicas of physical assetsto optimize energy usage in its manufacturing plants, achieving significant reductions in carbon emissions. These technologies help businesses comply with regulations, meet consumer demand for eco-friendly practices, and lower operational costs. As governments and consumers prioritize sustainability, industries are investing in smart technologies to create greener processes, further propelling the Industry 4.0 market forward.

Key Trends in the Industry 4.0 Market

- Rise of Digital Twins

Digital twins are emerging as a transformative trend in Industry 4.0, enabling companies to create virtual models of physical assets for real-time simulation and optimization. These digital replicas allow businesses to test scenarios, predict outcomes, and improve performance without disrupting operations. For instance, Airbus uses digital twins to simulate aircraft manufacturing processes, identifying inefficiencies and reducing production costs. This trend is gaining traction across industries like aerospace, automotive, and energy, as companies seek to enhance decision-making and innovation. By providing actionable insights, digital twins are reshaping how industries design, monitor, and maintain their operations, driving Industry 4.0 adoption.

- Integration of Artificial Intelligence and Machine Learning

The integration of AI and machine learning is a defining trend, enabling industries to process vast datasets and derive actionable insights. These technologies power predictive analytics, quality control, and autonomous decision-making. For example, BMW employs AI algorithms to analyze production line data, detecting defects in real time and improving product quality. Machine learning also enhances supply chain management by forecasting demand and optimizing inventory. As AI becomes more accessible, industries are embedding these technologies into their operations, creating smarter systems that adapt to changing conditions. This trend is accelerating the shift toward fully autonomous, data-driven industrial processes.

- Growth of Edge Computing

Edge computing is gaining momentum as a critical trend in Industry 4.0, allowing data processing closer to the source for faster decision-making. By reducing latency and reliance on cloud servers, edge computing supports real-time applications like autonomous robots and IoT devices. A case study is Amazons fulfillment centers, where edge computing enables real-time inventory tracking and robotic navigation, improving efficiency. This trend is particularly vital in industries requiring low-latency responses, such as manufacturing and logistics. As edge computing technologies advance, they enable more responsive and scalable industrial systems, solidifying their role in the Industry 4.0 ecosystem.

The industry 4.0 market report provides a comprehensive overview of the industry. This analysis is essential for stakeholders aiming to navigate the complexities of the biochar market and capitalize on emerging opportunities.

Leading Companies Operating in the Industry 4.0 Market Industry:

- Cisco Systems Inc.

- DENSO Corporation

- Fanuc Corporation

- Hewlett Packard Enterprise Company

- Intel Corporation

- International Business Machines Corporation

- Nvidia Corporation

- Robert Bosch GmbH

- SAP SE

- Schneider Electric SE

- Stratasys Ltd.

- Swisslog Holding AG (Kuka AG)

- Techman Robot Inc. (Quanta Storage Inc.)

Industry 4.0 Market Report Segmentation:

By Component:

- Hardware

- Software

- Services

Hardwareleads the market with around 49.8% share in 2024, serving as the physical backbone of Industry 4.0 through devices like industrial robots and sensors that collect real-time data for decision-making.

By Technology Type:

- Industrial Robotics

- Industrial IoT

- AI and ML

- Blockchain

- Extended Reality

- Digital Twin

- 3D Printing

- Others

Industrial IoT dominates with a 27.5% market share in 2024, enabling industries to gather extensive data for optimization and decision-making, with the market predicted to grow significantly by 2032.

By End Use Industry:

- Manufacturing

- Automotive

- Oil and Gas

- Energy and Utilities

- Electronic and Foundry

- Food and Beverages

- Aerospace and Defense

- Others

Manufacturing holds a 31.4% market share in 2024, as manufacturers adopt Industry 4.0 to enhance efficiency, reduce costs, and improve supply chain management through interconnected smart factories.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Europe accounts for over 35.8% of the market in 2024, driven by early adoption of Industry 4.0 technologies and strong government support for digitalization and sustainability initiatives.

Research Methodology:

The report employs acomprehensive research methodology, combiningprimary and secondary data sourcesto validate findings. It includesmarket assessments, surveys, expert opinions, and data triangulation techniquesto ensureaccuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the worlds most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145