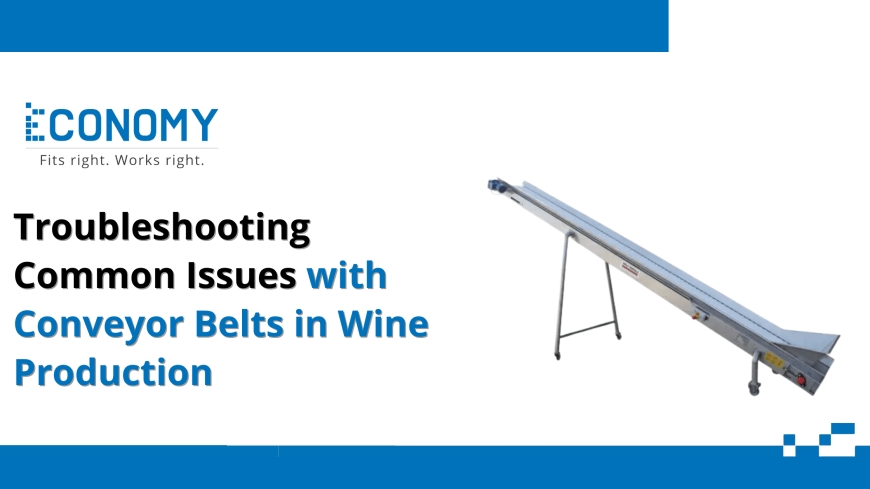

Troubleshooting Common Issues with Conveyor Belts in Wine Production

Conveyor belts are crucial for efficient and hygienic wine production. From misalignment to slippage and buildup, the range of possible issues is broad—but most can be avoided or quickly resolved with a well-structured maintenance routine.

Conveyor belts are the backbone of automation in modern wineries, streamlining operations from grape reception to final bottling. Their consistent performance ensures steady product flow and preserves the quality of wine throughout production. However, conveyor systems are exposed to a range of challengesgrape juice, skins, sticky residues, and continuous operationthat can lead to mechanical failures if not properly managed. Identifying issues early and applying effective troubleshooting and maintenance strategies is key to avoiding downtime and preserving productivity.

Identifying Conveyor Belt Problems in Wine Production

Wineries face unique conveyor belt challenges due to sticky organic materials, moisture, and temperature fluctuations. Common issues include misalignment, slippage, wear and tear, and hygiene concerns. Ignoring these problems can result in product contamination, reduced efficiency, and costly delays. Early detection through regular observation and inspection is essential to prevent small faults from escalating.

Misalignment of Conveyor Belts

One of the most frequent issues in wine production is belt misalignment. This occurs when the belt shifts off-center and starts to rub against the frame or side rollers.

Causes include:

-

Uneven loading of grapes or packaging materials

-

Misaligned pulleys or idlers

-

Debris accumulation on the return side of the belt

Consequences:

-

Uneven belt wear

-

Risk of spillage or mechanical damage

-

Increased power consumption

Slippage During Operation

Slippage is another critical issue where the belt loses traction with the drive pulley, leading to inefficient movement or complete stalling.

Primary causes:

-

Insufficient belt tension

-

Overloading during peak operations like grape crushing

-

Worn or contaminated pulleys

Symptoms:

-

Delayed material transfer

-

Belt "shuddering" or sudden jerks

-

Overheating motors due to increased load

Effective Solutions for Conveyor Belt Issues

Quick and accurate troubleshooting of conveyor issues helps wineries maintain smooth production. The following solutions address some of the most pressing problems:

Realigning Misaligned Conveyor Belts

Misalignment can usually be resolved with:

-

Adjusting the tension evenly across the belt width

-

Installing self-aligning idlers

-

Ensuring that pulleys are square to the frame and parallel to each other

-

Cleaning off built-up residue that may be skewing the belt path

Regular alignment checks can greatly extend belt life and improve safety.

Addressing Slippage with Proper Tensioning

Slippage is often corrected by adjusting the tension to ensure adequate contact between the belt and drive pulley. For effective tensioning:

-

Use gravity take-up or spring-loaded tensioners

-

Replace lagging on the drive pulley if it's worn or smooth

-

Avoid over-tightening, which can damage the belt or bearings

Monitoring belt performance under load is crucial to maintain the right tension balance.

Repairing or Replacing Damaged Belt Sections

Wear and tear are inevitable, especially in environments where grape seeds, stems, and sugars create abrasive conditions. Damage can be addressed by:

-

Replacing frayed or torn belt sections

-

Using food-grade patch kits for small punctures or cuts

-

Switching to modular plastic belts for easier cleaning and maintenance

Make sure all belt materials comply with food safety standards.

Implementing Industrial Cleaning Solutions

Sanitation is a top priority in wine production. Sticky residues can attract mold, compromise hygiene, and affect wine quality. To maintain cleanliness:

-

Use belt scrapers and cleaning brushes during operation

-

Implement CIP (Clean-in-Place) systems for thorough cleaning after shifts

-

Choose belts made from non-porous, easy-to-clean materials such as polyurethane or stainless steel mesh

Regular cleaning prevents buildup and reduces the risk of cross-contamination.

Proactive Maintenance to Avoid Downtime

A proactive approach to maintenance is essential in reducing unplanned downtime and prolonging the lifespan of conveyor systems. Scheduled checks can reveal signs of wear before they become serious issues.

Daily Inspection Routines

Operators should perform daily checks for:

-

Belt tracking and tension

-

Build-up of materials on pulleys and rollers

-

Loose fasteners, bolts, or brackets

-

Unusual noise or vibration from the motor or belt

Quick response to minor issues during inspections prevents major breakdowns.

Lubrication and Cleaning Best Practices

Proper lubrication reduces friction and heat generation, especially in bearings and gearboxes. Best practices include:

-

Using food-safe lubricants

-

Ensuring lubrication points are protected from contamination

-

Cleaning belts and conveyor frames regularly to avoid sticky buildup

Avoid over-lubricating, which can attract dust and grape debris.

Monitoring and Replacing Rollers

Rollers play a vital role in keeping the belt stable and moving smoothly. Wineries should:

-

Inspect rollers for flat spots or signs of wear

-

Replace damaged or seized rollers promptly

-

Opt for stainless steel or polymer rollers resistant to corrosion

A worn roller can lead to misalignment and uneven belt wear.

Seasonal Maintenance Tips for Wine Producers

The grape harvest season places extra strain on conveyor belts. Before and after the harvest:

-

Deep-clean conveyor systems

-

Inspect and replace worn belts, bearings, or motors

-

Calibrate tensioners and tracking systems

-

Review and update maintenance logs and spare parts inventory

Preparing ahead of the busy season ensures smoother operation and fewer unexpected breakdowns.

Keeping Your Conveyor Belts Running Smoothly

Conveyor belts are crucial for efficient and hygienic wine production. From misalignment to slippage and buildup, the range of possible issues is broadbut most can be avoided or quickly resolved with a well-structured wine industry conveyor belt maintenance routine. Through regular inspections, proper tensioning, strategic cleaning, and timely part replacements, wineries can maximize conveyor reliability and keep production running smoothly throughout the year.